One of the issues we have in our dining room is that one of the previous building owners removed a relieving wall below the parlor. As a result a portion of the floor has begun to sag about 2-1/2″ to 3″ over a 12′-0″ span which is typical in these old brownstones. It is very noticeable when you walk across the floor. Additionally a renovation was done back in the 60’s or 70’s and instead of shimming the floor they used about 3-1/2″ of concrete to level it along with 7″ of solid plaster furring on the walls to accommodate a 60″ tub in a room that was 67″ wide.

Needless to say when we demoed this area of the house and removed the concrete and plaster, the floors began to spring back into shape. This room is currently a candidate for the biggest loser. We also noticed that much of the plaster around the ceiling had begun to crack and split under the pressure as the floors moved back up. Oh well, you can’t think of everything. Had I known this was going to be the case we would have removed a 1″ strip of plaster around the ceiling to prevent any damage to it to the delicate cove mouldings.

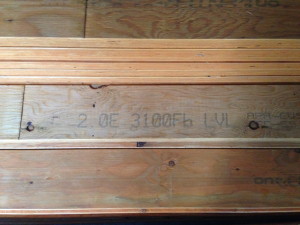

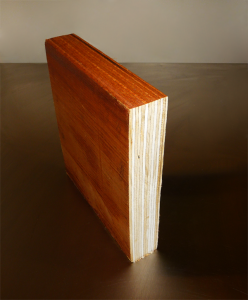

Unfortunately there is still a significant amount of sag in this area and we are going to remedy the remainder of deflection and sag with a triple LVL beam and jacking posts. Its a relatively simple and easy fix if you know how to manage cracking plaster and which posts to buy. While I don’t think we will ever get the floor back to zero sag, we can make the condition significantly better and keep the floor from deflecting any further. Yesterday the contractors built the beam that we are going to install today and hopefully next week we can begin to slowly jack the floor back into shape…

Disclaimer: Don’t try this without a trusty engineer. You can do a lot of damaged quickly to a building and you certainly don’t want to lift it off the foundations…

Disclaimer: Don’t try this without a trusty engineer. You can do a lot of damaged quickly to a building and you certainly don’t want to lift it off the foundations…